Challenges of Traditional Craftsmanship in Aerospace Production:

1.Complexity of Components: Aerospace parts often have intricate designs and precise specifications that are difficult to achieve with traditional methods like machining or casting, requiring high levels of skill and manual work.

2.High Production Costs: Traditional methods often involve expensive materials and labor-intensive processes, making the production of aerospace components costly, especially for low-volume or prototype parts.

3.Material Waste: Traditional manufacturing methods tend to create significant material waste, which can increase costs and environmental impact, especially when producing complex or custom parts.

Advantages of Using 3D Printing in Aerospace Production:

1.Design Flexibility: 3D printing allows the creation of complex and customized components that would be difficult or impossible to produce using traditional methods, enabling innovation in design.

2.Cost Efficiency: 3D printing reduces material waste and can lower production costs, especially for small runs or prototypes, making it more economical compared to traditional manufacturing.

3.Rapid Prototyping: With 3D printing, aerospace companies can quickly produce prototypes for testing and iteration, significantly reducing the time required to bring new designs to market.

SLA Technology

SLA (Stereolithography) 3D printing is ideal for aerospace applications due to its ability to produce highly detailed, precise, and complex parts with smooth surfaces. It enables rapid prototyping and the creation of intricate geometries, which is crucial for designing lightweight, high-performance components. SLA also supports the use of specialized resins, providing durability and high thermal resistance needed for aerospace products.

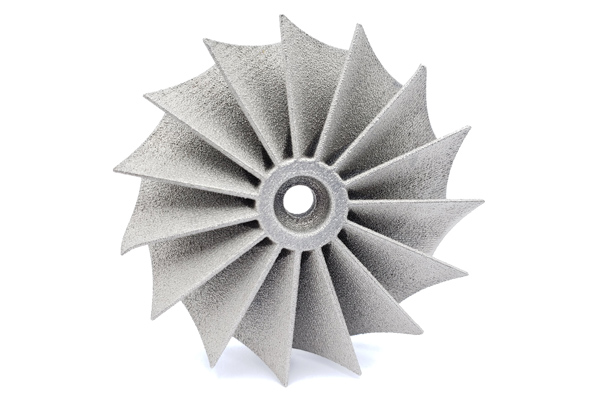

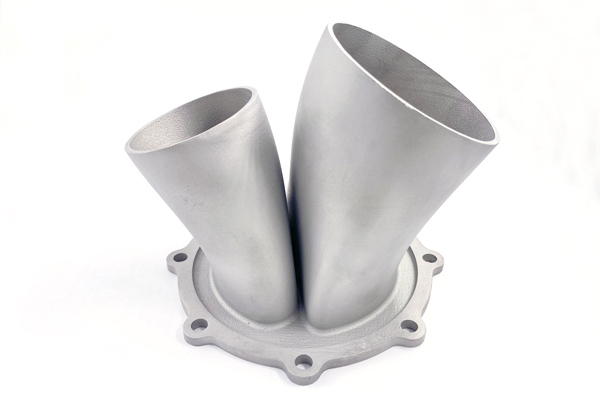

SLM Technology

SLM (Selective Laser Melting) 3D printing is highly suitable for aerospace products due to its ability to create strong, lightweight, and complex metal components. It offers precise control over material properties, making it ideal for high-performance parts that require exceptional strength, heat resistance, and durability. SLM enables the production of intricate geometries, reducing material waste and allowing for the creation of optimized, custom-designed aerospace components.

If you' re interested in learning more about the applications of 3D printing feel free to Click Inquiry Now